24-hour hotline:

0536-3913110 13869681357 (Domestic) 18906461921 (Overseas)

Tel: 0536-3913110

Fax: 0536-3717899

Mob:

13869681357(Domestic)

18906461921(Overseas)

Add: No. 2707, Nanerhuan Road, Linqu district, Weifang City, Shandong Province, China.

Email: cortelaser@163.com

Material application

Suitable for precision machinery, hardware, sheet metal processing, etc. It is especially suitable for stainless steel, iron plate, aluminum plate, copper plate, diamond saw blade and other materials, and has excellent processing effect on all kinds of high hard and brittle alloys.

Industry application

Kitchen appliances, sheet metal cabinet, mechanical equipment, hardware lighting, door&window manufacturing, advertising signs, auto parts, decoration, shipping and aviation, medical equipment, mining equipment, animal husbandry machinery, agricultural machinery, iron tower industry, clothes hanger, shelf and metal processing industry

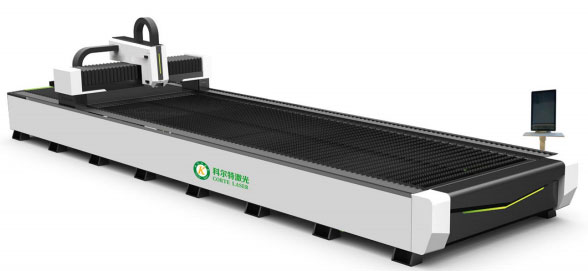

Features:

(1) The cutting width is 2500-3500mm, and the length is 12000-24000mm, which can realize that the whole plate can be cut and shaped once and improve working efficiency.

(2) The table is equipped with a small manual wheel frame, and the cut plate can slide and move along the bed, which is convenient for feeding.

(3) The electric air claw tightens thin plate conveniently and quickly.

(4) The cantilever beam is a casting type with reliable structure and good rigidity, which makes the mechanism run more smoothly.

(5) The laser focus automatically follows. The metal sheet must be shaped into a plane by the original winding before cutting, then the plate plane will inevitably have some “ups and downs”, and the focus auto-following structure can ensure the focus plane and the plane of the cut plate.

(6) Maintain a constant distance, so that cutting quality is always consistent, to avoid “ups and downs” brought about by bad products.

(7) The cost of the laser is low and maintenance is convenient. The operator can replace the consumables and maintain the equipment by himself after training.

(8) Fiber lasers of different powers or manufacturers can be selected

Technical parameters:

Processing format: X format 2450mm/2550mm/3050mm/customized

Y format 12000mm/18000mm/24000mm/customized

Max. operation speed: 80m/min

Max. acceleration: 1.5G

X/Y positioning precision: ±0.02mm

X/Y repeating positioning precision: ±0.02mm

Laser power: 20000W/12000W/6000W/4000W/3000W/2000W/1000W

Operation voltage: 380V, 50Hz

Operation temperature and humidity of machine tool: 0℃-40℃, <90%

Driving mode: Precision rack dual drive